Piezo Switch Function

On this page

Functional Description Piezo Switch NO

The piezo switch is based on the functional principle of the piezoelectric crystal. The action of force on the piezo disc causes a voltage to be induced due to a charge transfer. The voltage generated is converted by the electronic connection into a polarity-neutral, electronic switch contact.

During the voltage drop, the electronic switch contact is closed for the specified pulse duration. After this, the electronic switch contact opens again, even if the force is still present. The period that the electronic switch contact remains closed depends on the actuating speed and force as well as on the duration of actuation.

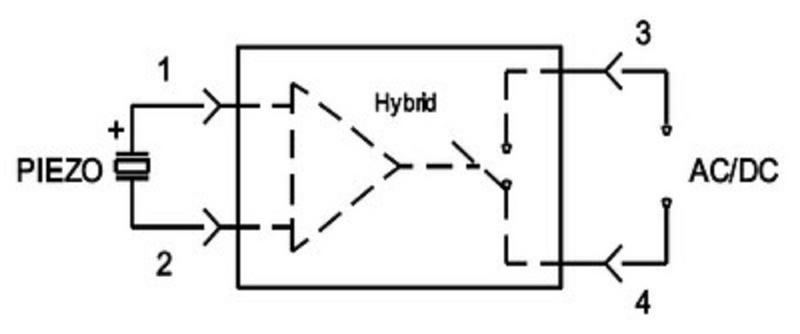

Diagram of a NO switch:

The piezo disc is connected to the terminals 1 and 2. The electric circuit to be switched is connected at the terminals 3 and 4. This can be either direct voltage (DC) or alternating voltage (AC). If a pulse is applied to the piezo disc, terminal 1 becomes positive in relation to terminal 2 due to the voltage generated. The integrated switching element controls the electric circuit to be switched.

In the neutral position of the piezo switching element, the terminals 3 and 4 are non-conductive, and initial switch resistance is > 10 MOhm. When the piezo disc is actuated, the initial switch resistance is reduced to < 20 Ohm. When actuating the piezo disc, the resistance between terminals 3 and 4 is therefore changed from high resistance → low resistance → high resistance.

This corresponds in principle to the function of a conventional NO pushbutton switch.

Functional Description Piezo Switches Illumination

Ring Illumination

Single or bi-colored ring illumination is possible for the PSE switches.

When equipped with two colors, it is possible to either switch between the colors or to achieve a combination color, depending on the type of activation.

For example: Diodes of group 1 = red and diodes of group 2 = green

Only group 1 is activated → Ring has red illumination

Only group 2 is activated → Ring has green illumination

Both groups are activated at the same time → Ring has orange illumination

Red cable = Supply voltage: red LEDs

Green cable = Supply voltage: green LEDs

Black cable = Minus for all LEDs

White cable = Switch contact

Terminal layout:

Ring Illumination for M24, M27, M30 series - 12 / 24 VDC

Ring Illumination for M22 series - 12 / 24 VDC with Wires

Ring Illumination for M22 series - 12 / 24 VDC with Plug Connector

Ring Illumination Special Type 5 VDC - on request

Point illumination

When illuminating the PSE switch, either a single-color LED (2 pins) is used or a bi-colored LED (3 pins). If a single-color LED is used, cable No. 2 is not needed (see terminal layout).

Switching between colors can be achieved by appropriate activation.

Terminal Layout:

Point illumination

Annotation for the Protection of Piezo Switch PSE EX

The explosion-proof piezo switch PSE EX has the function of a NO switch (normally open / NO). The permissible voltage and current of the PSE EX switch are limited, so that the PSE EX is intrinsically safe in accordance with EN60079-11. The electrical characteristics are listed under Specifications. The use of the PSE is therefore permitted only in areas where the formation of explosive atmospheres caused by gases, fumes, mist or dust mixing with air occurs occasionally. The PSE EX has a high degree of security that is also effective at common equipment malfunctions or errors. The explosion-proof PSE is classified according to EN 60079-0 in the device group II, category 2.

Please note:

- The permissible operating temperature is -20°C to +60°C.

- Operation approval expires on removal of the type label.

- Installation in accordance with IEC / EN 60079-14 and IEC / EN 60079-25.

What does the information in the approvals mean?

Sie gebe die Einsatzbereiche, in denen der PSE EX zugelassen ist, an.

II

Equipment Group

For use in all potentially explosive atmospheres except firedamp-prone mine workings (mining)

2

Category

For zone 1 and 21, occasionally explosive atmospheres

G

Category

Use in flammable gases, vapors, mists

D

Category

Use in combustible dusts

Ex

Part marking

Marking of the Ex-conformity

ib

Ignition protection type

Intrinsic safety of the circuit, no ignition spark (ne fault case)

IIC

Explosion group

For operating equipment in explosive gases, vapors, mists

IIIC

Explosion group

For equipment in explosive dusts

T6/T5

Temperature class

Maximum permissible surface temperature T6=85 C/T5=100 C

Gb

Protection class

For devices of protection class Gase with intrinsic safety

Db

Protection class

For devices of protection class dusts with intrinsic safety

Connecting technology and switching options

![]()

1. Decoder

The metallic panel keypads are designed with an XY matrix. The PC keypads are available with a corresponding keypad decoder and can therefore be used as standard in German, British and U.S. versions. Further country-specific programming can be realised according to customer requirements ex works.

2. Interfaces

Depending on the version, AT PS/2 or USB connections are available as ports with mini-DIN or USB connectors.

3. Connecting technology

Depending on the design, the switches are available with quick connect terminals, flexible wires, pins or clip for pins. Plug-compatible adapters are available for the MCS 19 to achieve rational wiring of components.

4. Switching options

High capacity with the SCHURTER power card: the small design of the piezo switches only allows the switching of small signals or powers in general. With the SCHURTER power card, which is connected directly to the piezo switches, large powers can also be switched. The relays on the SCHURTER power card allow higher voltages, currents and powers to be used and significantly extend the range of applications of the piezo switches.

Increased ease of use is offered for the piezo switches by the prolonged signal version from SCHURTER. Piezo switches usually have a short closing pulse which depends on the activating force, duration and speed. For the piezo switches with prolonged signal, the signal is passed on for the duration in which the switch is pressed (max. 50 seconds).

Protection against pyroelectric effects for the piezo switches with prolonged signal is provided by a specially developed circuit which compensates any pyroelectric effects resulting from the occurrence of large changes in temperature. The switches with integral temperature compensation are of course tested for functional safety by using specific individual tests.