Automotive

Protection of electronics in automotive engineering

Automotive

Approved solutions for a dynamic market

Security through innovation and commitment

Engineering

We, as an electronic components manufacturer, develop together with and for our customers solutions to use in their automotive applications. Mature technologies are used to achieve the customer's specific requirements that normally exceeds the standardized requirements. The custom required production process and documentation lead beyond to customized production.

Innovation

Innovations in safety and environmental systems, more comfort and safety are the driving forces, which lead the trend towards more and more sophisticated on-board electronic applications. Electronic controls and power supply depend on a high degree of reliability and long-term stability of all components. Chip Fuse are precise, reliable, temperature resistant and robust against vibrations. These characteristics make them ideal for the use in automotive applications.

Our solutions

We offer solutions for the various applications in the automotive industry. In addition to a safe power supply during the charging process for electric vehicles, our products ensure protection of the battery, the inverter for the motor drive and the air conditioning systems, protection of the ignition system and emergency power supply as well as the provision of intuitive operating elements.

Electric mobility on the rise

Electric vehicles (EVs) are playing an increasingly important role in our mobility. Charging speed plays a decisive role. With fast charging, the alternating current is converted directly into direct current at the charging station. The DC converters used in this process must be as efficient as possible in order to minimise energy loss. However, more efficient DC conversion also means higher electromagnetic emissions. The attenuation of these emissions is of central importance, as they must not be allowed to enter the power grid or the connected electric vehicle as interference signals. Insufficiently attenuated signals can interrupt the communication protocol between the charging station and the vehicle. In the worst case scenario, this can even lead to defects in the vehicle. We offer various products for use during the charging process.

SCHURTER UHP-SMD Fuse for High-Power Lithium-Ion Batteries

In the world of electronics, especially in the automotive industry, the demand for high-performance solutions up to 48 volts DC is ever-growing. To reliably safeguard higher operating currents, look no further than the SCHURTER UHP fuse. This remarkable component is engineered to break the circuit at twice the rated current, all within a maximum of 15 seconds.

Components for ignition systems

Application

Protection of the ignition system. Various influences lead to fluctuations, which must be secured by suitable means.

RTS

SMD thermal fuse with a tripping temperature of 175°C and 210°C. Rated voltage up to 60 VDC. Version with shunt available.

USN 1206

Thermal sensitive SMD fuse. At ambient temperatures around 200 °C, the required tripping current is reduced and thus additionally protects against thermal runaway.Components for climate control

Application

Protection of ventilation, heating and air conditioning systems.

FMEB / FMEC

Single or dual pole DC filter. 1-stage line filter in standard version. Compact and light weight design.

RTS

SMD thermal fuse with a tripping temperature of 175°C and 210°C. Rated voltage up to 60 VDC. Version with shunt available.Products for control elements

Application

Switches and input systems for simple and intuitive operation.

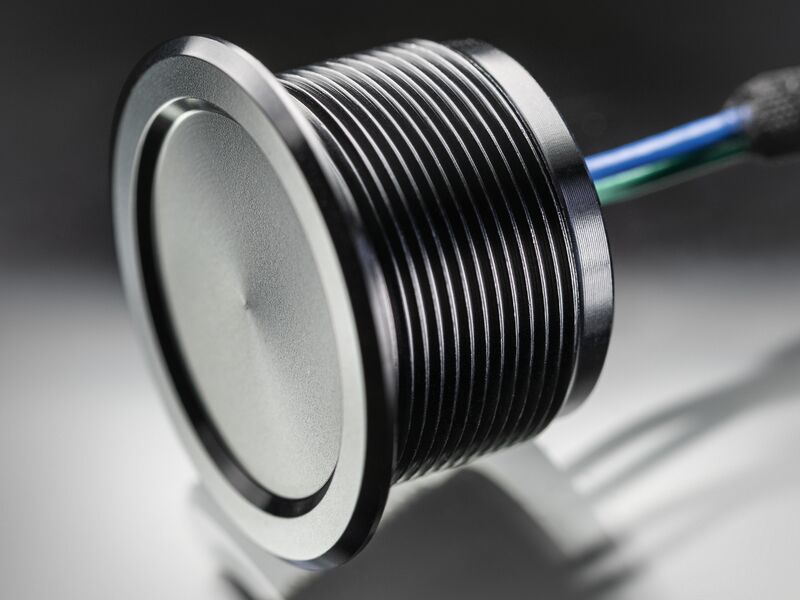

PSE

Piezo switch with housing material types: aluminum, brass chrome-plated or stainless steel. Long lifetime with more than 20 Mio. actuations.

MSM

Metal Line switch. Attractive tactile feedback. Long life span. Single color or homogeneous RGB illumination.EV Charging Systems

As a manufacturer of electronic components, we offer reliable and robust electronic components and HMIs that will ensure the smooth operation and longevity of your electric vehicle charging stations.

Find out all our EVSE-friendly electronic components tailored for your housings, enclosures and connectors.

EMC Measurement Service

Our team of EMC specialists offers a comprehensive, professional measurement service to ensure electromagnetic compatibility (EMC):

We carry out EMC tests on your behalf.

We suppress interference in your electrical systems.

We fault-clean your electrical appliances.

We support you from development to series production.

Our measurement report serves as proof of CE conformity.

On request directly on site!

SCHURTER certified according to IATF 16949

On 10 August 2017, SCHURTER AG in Lucerne successfully passed the audits for the certification according to the new Automotive Standard IATF 16949: 2016. This new standard of the IATF (International Automotive Task Force) places the highest demands on the system and process quality of a company.

SCHURTER has pursued this certification with the clear goal of further developing its own company. SCHURTER intends to improve continuously in order to meet the ever-growing demands of its customers today and in the future.

After clean analyzes, internal processes were optimized, the documentation of all products and production processes refined down to the last detail. Management has also been compelled: in the future, it will be more involved in all process and production phases.

The interdisciplinary and process-oriented is gaining in importance. The goal is clearly defined: the reliability of the processes is increased and thus the product quality is maintained at a high and - most importantly - constant level. Zero errors are the goal. An objective that requires a continuous optimization process.

Stay up to date with the latest news

Documents and references for automotive technology

Discover more about the regulations and our specific products:

White paper "Rolling Jamming Transmitters"

White paper "AEC-Q200"

You will be transferred to the selected country page address. Therefore you will leave the SCHURTER main page.

You will be transferred to the selected country page address. Therefore you will leave the SCHURTER main page.